We were given a scenario and usecase for a filter fiber for use in a wastewater system. From this scenario, we were tasked with designing a filter fiber suitable for the situation through technology and software like Granta EduPack.

Our scenario concerned a hospital in rural Byron Bay, Australia. Local residents were concerned that the hospital's effluent contained antibiotics such as ciprofloxacin, which were not adequately filtered out. These antiobiotic strains could cause damage to the environment.

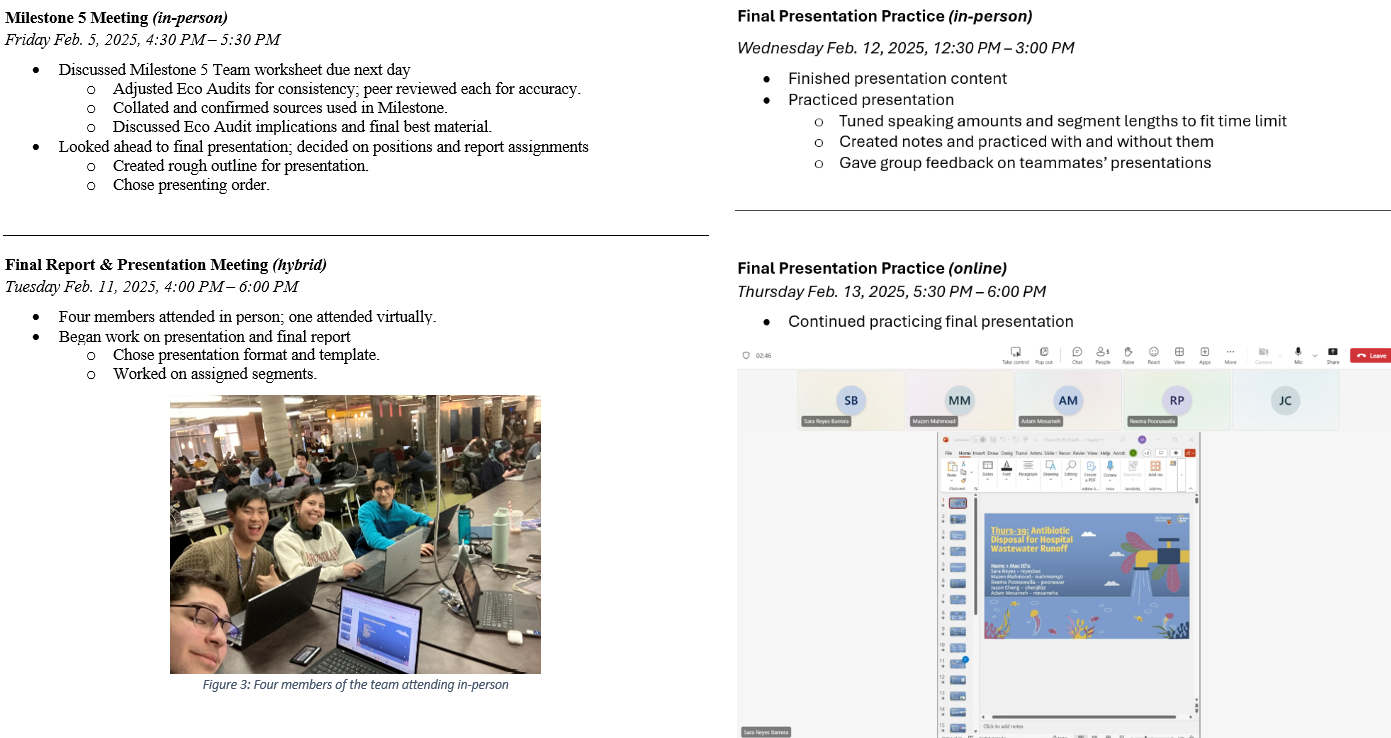

Technical Objectives:A set of objectives, constraints, and other goals were compiled, using organizational structures to organize our ideas. I led talks on the creation of an objective tree, suggesting key items such as modularity, weather friendliness (taking into account Australia's climate), and other restructuring, such as merging "low maintenance" and "repairable" into the same category. See Fig. 1.

Fig. 1: Final objective tree used as brainstorming.

Finally, taking into consideration all objectives and constraints developed in the brainstorming, three were chosen: "environmentally friendly", "cost-effective", and "low/easy maintenance". A problem statement was created to inform the future of the project.

Problem Statement:The primary function of the filter is to effectively remove ciprofloxacin molecules from the wastewater before it is released into the environment. We aim to design a cost-effective, environmentally sustainable, and low-maintenance system that can handle large volumes of wastewater while considering the rural hospital's limited budget and staffing constraints and the containment size of $5\text-10 \; \mu \text{m}$.

High-level objectives include ensuring the filter is durable, easy to maintain, and capable of preventing the spread of antibiotic-resistant bacteria, ultimately protecting both the environment and the health of the local community.

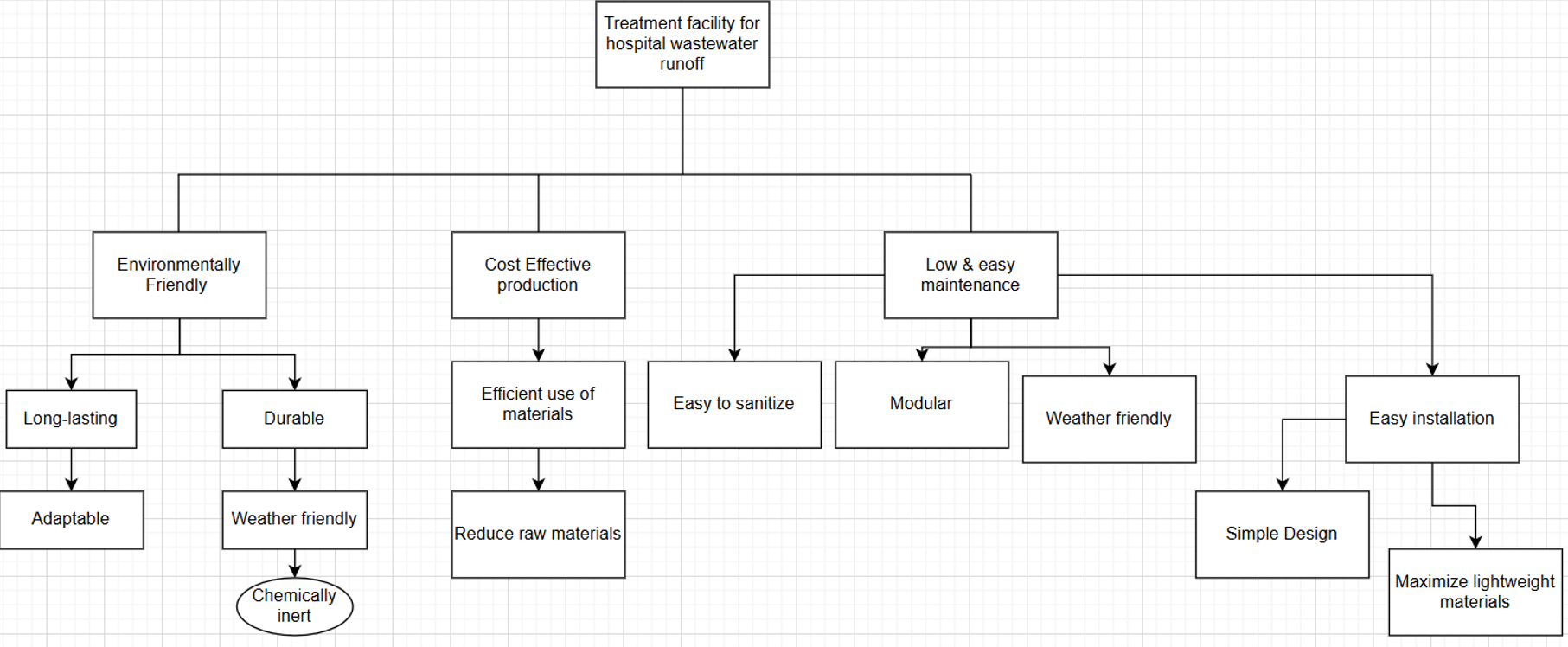

Research:Research was done to find means of accomplishing the objectives. These means aimed to be varied, with the goal of capturing the solution space. First, I wrote an executive research summary on the current state of filtration technology fitting to our scenario. Then we made a morph chart (Fig. 2).

Fig. 2: Morph chart of means to accomplish each objective.

Afterwards, research was done on numerous real-world concerns: potential materials, contaminant/waste standards, electricity standards, optimal placement, and other relevant regulation.

Through weighing the cost of benefits of each means carefully, ozonation was judged to be the most sustainable and efficient method of filtration, I researched potential material acquisition, finding pertinent information on laws on materials and wastewater for Eastern Australia.

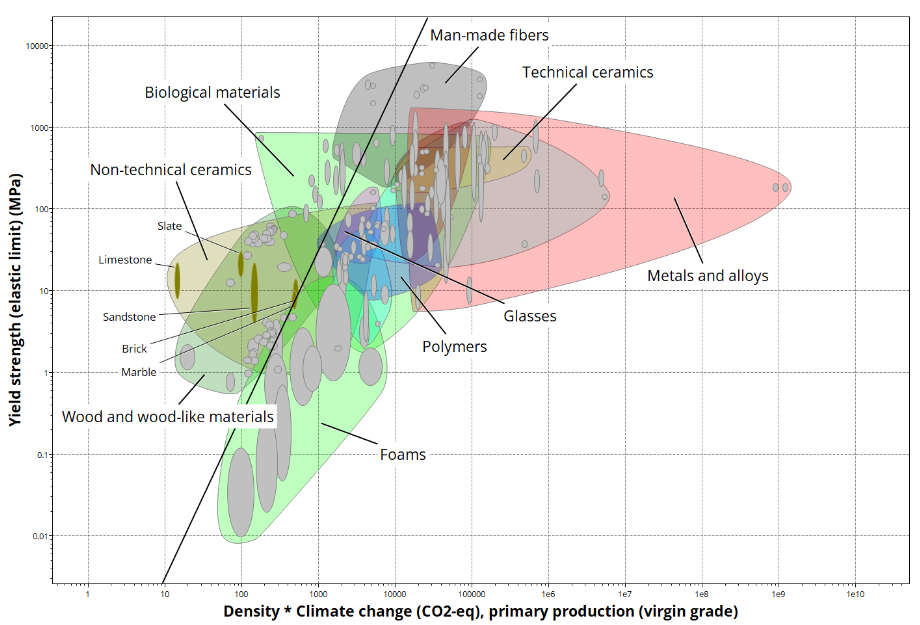

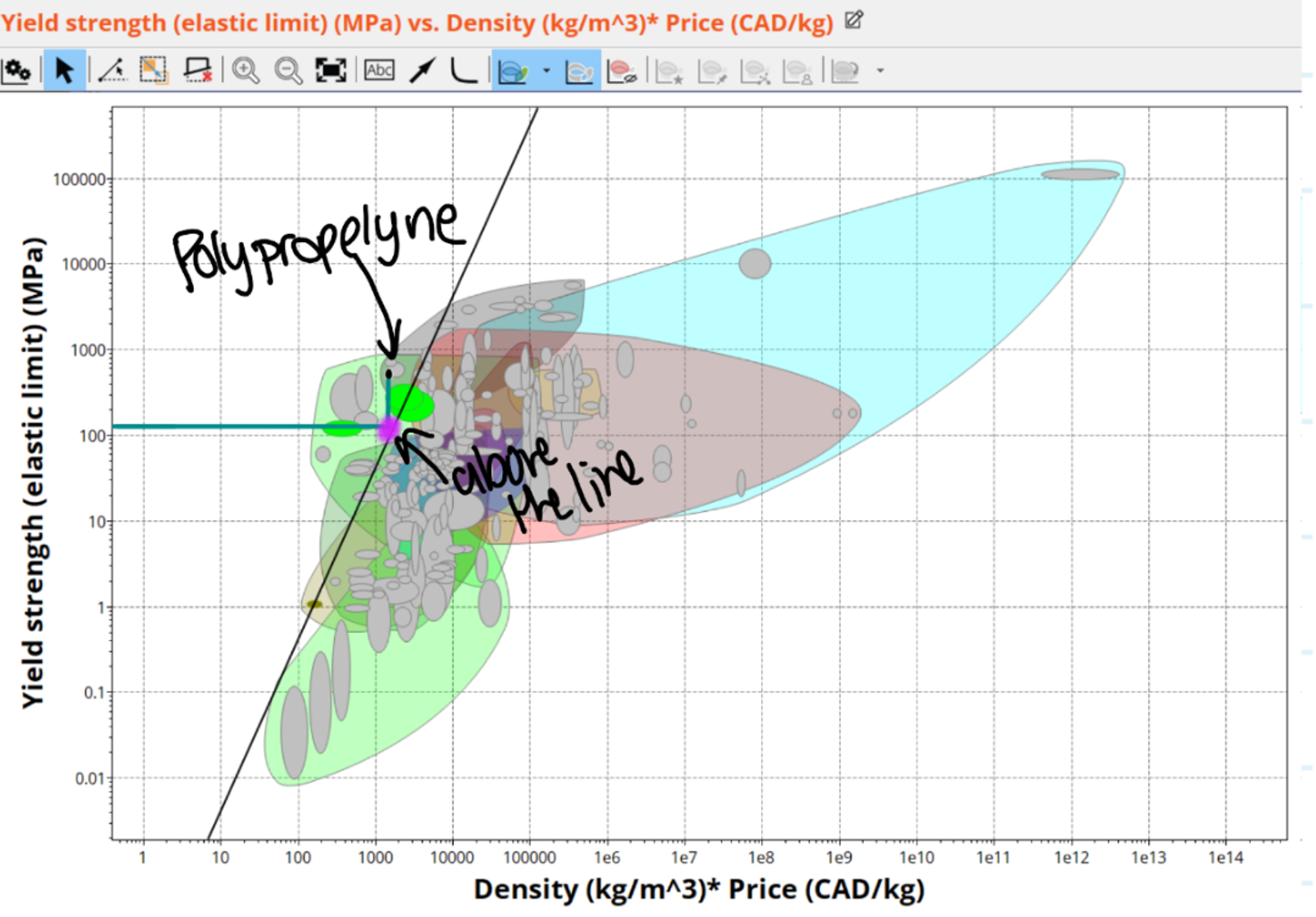

MPIs:MPIs were derived for the objectives. I was assigned the MPI of minimizing carbon footprint $\text{CO}_2$, while optimizing for yield strength $\sigma$. Using the provided functional constraint for $\sigma_y$, the MPI was derived: $$ \begin{align*} m &= ALP & \sigma_y &> \frac{6FL}{bh^2} \\ m &= bhlP & \sigma_y &> \frac{6FL}{b(\frac{m}{bLP})^2} \\ h &= \frac{m}{bLP} & \sigma_y &> \frac{6FL}{\frac{bm^2}{b^2L^2P^2}} \\ \text{subst}&\text{ituting } h \nearrow & \sigma_y &> \frac{6FLbL^2P^2}{m^2} \\ && \sigma_y &> \frac{6FL^3bP^2}{m^2} \\ && m^2 &< \frac{6FL^3bP^2}{\sigma_y} \\ && m &< \sqrt{6FL^2}\frac{P}{\sqrt{\sigma_y}} \\ && MPI &= \frac{\sigma_y^{1/2}}{P} = \frac{\sigma_y^{1/2}}{\rho \cdot \text{CO}_2} \end{align*} $$

This MPI along with the two constraints Freshwater Durability (excellent), Built Environments (rural), were used in the materials database Granta EduPack to find the optimal materials for the project.

Fig. 3: The resultant chart from my MPI and constraints.

Upon comparison of my Top 3 materials with my teammates' materials, a final Top 3 was found:

- Coir fiber

- Polypropylene fiber

- Limestone

The number of pores for our material was calculated, then the porosity of the overall fiber, then the effective Young's Modulus and yield strength for the material.

In the resultant chart (Fig. 4), polypropylene satisfied the required yield strength of $154 \; \text{N} / \text{m}^2$.

Eco Audits

Fig. 4: The chart, showing polypropylene above the line.

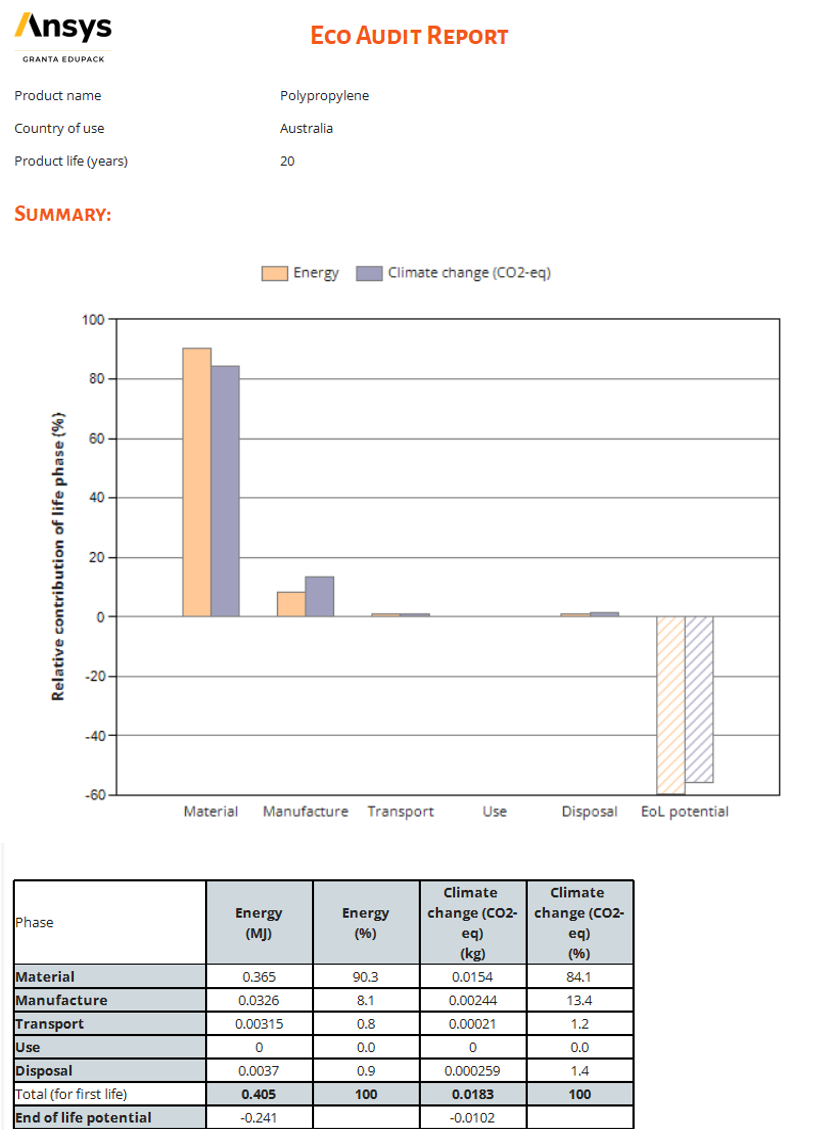

Finally, Granta Eco-Audits (Fig. 5) were performed to test the material's ecological performance.

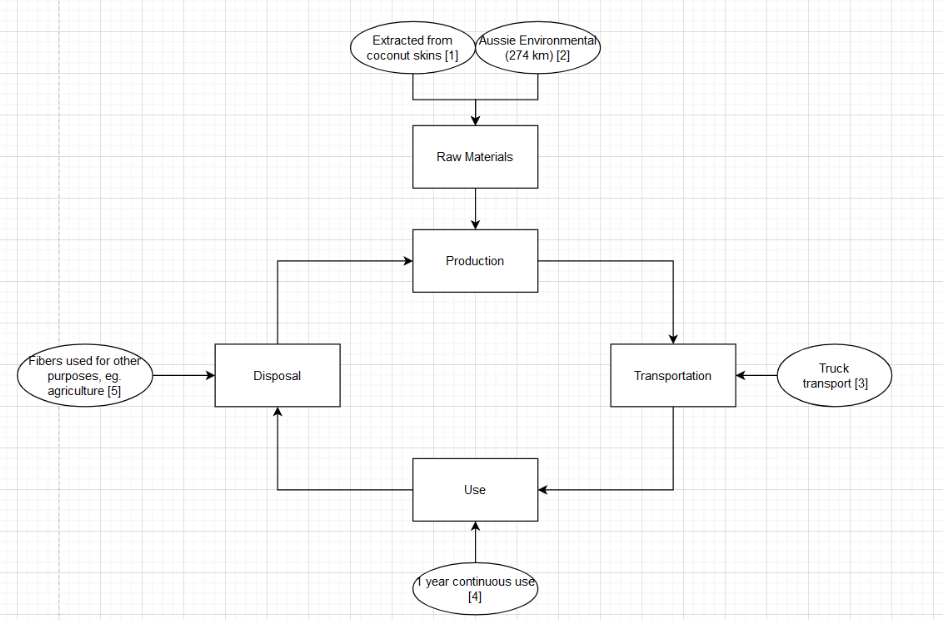

I created a life-cycle diagram (Fig. 6) for my assigned material of coir fiber, as well as the Eco-Audit for it. It confirmed that while polypropylene used the most energy, it had the most potential for recycling and use after its end of life.

Presentation:We created a ~10-minute presentation on our process and findings, and I created, wrote, and presented the content for the slides:

- MPI

- Material selection

- Objectives/constraints

Fig. 5: The Eco-Audit for polypropylene.

Fig. 6: My life cycle analysis diagram for coir fiber.

■